Automatic Cement Hollow Block Making Machinery Made in Ghana Interlocking Brick Moulding Machine for Sale Zimbabwe

automatic block making machine

automatic brick machine

automatic block machine

automatic brick making machine

brick machine automatic

automatic cement brick making machine in algeria

concrete block machine automatic

fly ash bricks making machine automatic

fully automatic block making machine

automatic concrete block machine

automatic concrete block making machine

automatic interlock brick machine

brick making machine automatic

Description

a. Raw material use wheelloader delivery into batching machine , need 1 worker

b. Cement delivery into mixer, from cement silo by cement screw conveyor

c. Mixer mixing material, then delivery to brick machine (9) by conveyor here need 1 worker

d. After produce blocks, block receiver , delivery blocks to stacker

e. Forklift ( delivery blocks to curing area , need 1 worker

f. Curing area : Curing need 10-15 days, then take blocks out from pallet; need 1-2 workers

g. After curing, take blocks out from pallet, pallet delivery to Pallet feeding machine by forklift

Blocks laying in block stock area

h. Sell blocks: Sell blocks and management; 1 worker

Total need about 5-6 workers in QT4-18 automatic interlocking block machine factory.

2.QT4-18 Hydraulic Automatic Block Production line

Dimension of host machine |

3600*1500*2400mm |

Power of host machine |

19.2KW |

Weight of host machine |

4000kg |

Vibration force |

26KN |

Size of palllet |

850*550*25mm |

Model of mixer |

JQ500 |

Rated Voltage |

220v/380v |

Forming period |

18-20s |

A |

MACHINE NAME |

FUNCTION |

B |

QT4-18 brick machine |

1.pallet feeding system 2.Material feeding system 3.Brick molding system |

C |

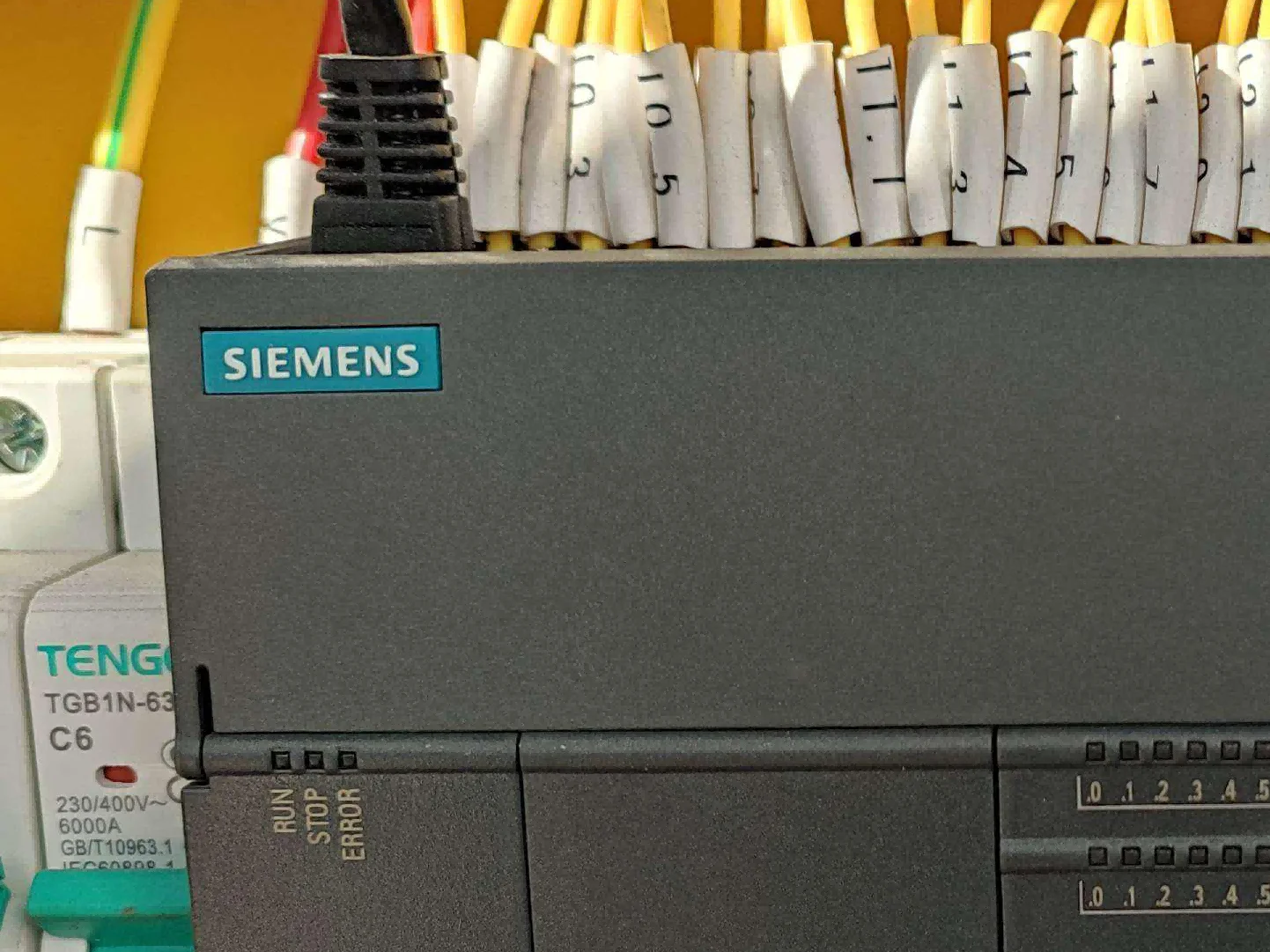

PLC controller |

Control the full brick product line by automatic PLC ,full automatic one. |

D |

Hydraulic station |

Supply the hydraulic power for full line |

E |

JQ500 Mixer |

Mix material automatically for brick production |

F |

block receiver |

Convey the completed brick |

G |

Stacker, it could layer 4-5 pallets blocks |

Convey the brick pallet by pallet to the manual trolley |

H |

Manual forklift trolley (2 pcs) |

Convey bricks to curing place |

Optional systerm |

Color feeder machine |

Spread color on bricks(only colored bricks need |

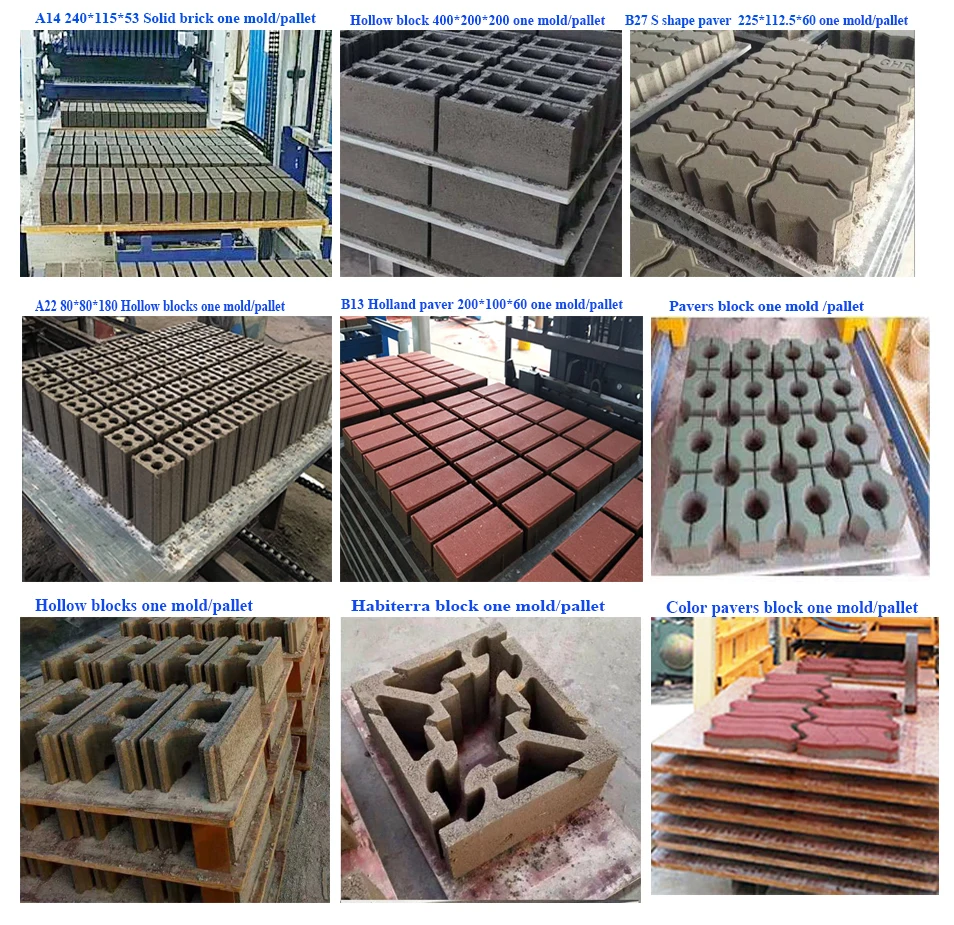

Size (L*W*H)mm |

Pcs/mold |

Pcs/hour |

400*200*200 |

4 |

600~800 |

240*115*53 |

26 |

5000~5200 |

200*100*60 |

14 |

4600~4800 |

FUDA block making machine factory introduction

Fuda Brick Making Machine Factory provides comprehensive after-sales support to their clients, including training, installation, and maintenance services. The company also offers a warranty on their products, ensuring that their customers can have peace of mind when using their machines.

Overall, Fuda Brick Making Machine Factory is a reliable manufacturer of brick making machines with a proven track record in the industry. We offer quality products at affordable prices, making them a good choice for those looking for a brick making machine supplier in China.