What's the process of starting a concerte block making factory

Starting a concrete block-making factory involves several steps, from planning and research to execution and operation. Here's a detailed guide to help you through the process:

1. Market Research and Feasibility Study

Demand Analysis: Assess the demand for concrete blocks in your target market. Identify potential customers such as construction companies, contractors, and individual homeowners.

Competition Analysis: Study existing competitors, their products, pricing, and market share.

Feasibility Study: Determine the financial viability of the project. Consider factors like initial investment, operational costs, and potential revenue.

2. Business Plan Development

Executive Summary: Outline your business goals, mission, and vision.

Market Strategy: Define your target market, pricing strategy, and sales channels.

Operational Plan: Detail the production process, equipment needed, and supply chain management.

Financial Plan: Include projected income statements, cash flow statements, and balance sheets. Estimate startup costs, working capital, and break-even analysis.

3. Legal and Regulatory Compliance

Business Registration: Register your business with the appropriate government authorities.

Permits and Licenses: Obtain necessary permits and licenses for operating a manufacturing facility.

Environmental Regulations: Ensure compliance with environmental regulations related to waste management and emissions.

4. Site Selection and Setup

Location: Choose a location with easy access to raw materials and target markets. Ensure adequate space for production, storage, and office facilities.

Infrastructure: Set up the necessary infrastructure, including utilities like water, electricity, and transportation facilities.

Factory Layout: Design an efficient layout for the production line, storage areas, and office space.

5. Procurement of Equipment and Raw Materials

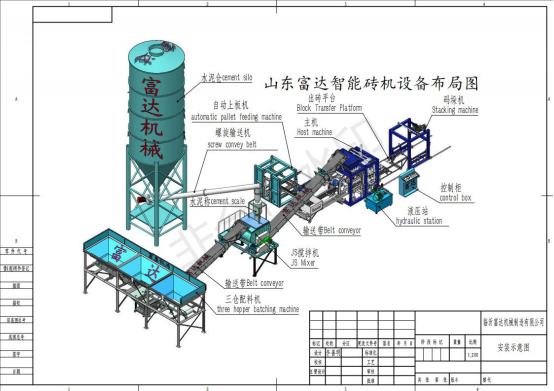

Equipment: Purchase or lease concrete block-making machines, mixers, conveyors, and molds. Consider the production capacity and automation level based on your business plan.

Raw Materials: Source quality raw materials such as cement, aggregates (sand, gravel), and water. Establish reliable supply chains to ensure consistent production.

6. Production Process Setup

Mixing: Combine cement, aggregates, and water in the correct proportions to create the concrete mix.

Molding: Use molds to shape the concrete mix into blocks. This can be done manually or using automated machines.

Curing: Allow the blocks to cure and gain strength. This can be done through natural curing or using steam curing chambers for faster results.

Quality Control: Implement quality control measures to ensure the blocks meet industry standards and customer expectations.

7. Staffing and Training

Hiring: Recruit skilled and unskilled labor for various roles such as machine operators, quality control inspectors, and administrative staff.

Training: Provide training on operating machinery, safety protocols, and quality standards.

8. Marketing and Sales Strategy

Branding: Develop a strong brand identity, including a logo, packaging, and marketing materials.

Distribution Channels: Establish distribution channels such as direct sales, partnerships with construction companies, and retail outlets.

Promotion: Use advertising, social media, and trade shows to promote your products. Offer samples and discounts to attract initial customers.

9. Launch and Operations

Soft Launch: Start with a soft launch to test the production process and gather feedback.

Full-Scale Operations: Gradually scale up production based on market demand and feedback.

Continuous Improvement: Regularly review and improve processes, product quality, and customer service.

10. Financial Management

Budgeting: Monitor and control expenses to stay within budget.

Cash Flow Management: Ensure sufficient cash flow to cover operational costs and invest in growth.

Profitability Analysis: Regularly analyze profitability and make adjustments as needed.

11. Scaling and Expansion

Market Expansion: Explore new markets and regions for expansion.

Product Diversification: Consider diversifying your product line to include different types of concrete blocks or related products.

Technology Upgrades: Invest in advanced technology and automation to increase efficiency and reduce costs.

12. Sustainability and Corporate Social Responsibility (CSR)

Sustainable Practices: Implement eco-friendly practices such as recycling waste materials and reducing energy consumption.

Community Engagement: Engage with the local community through CSR initiatives and support local development projects.

By following these steps, you can establish a successful concrete block-making factory that meets market demands and achieves long-term growth.