How do I go about starting a concrete block manufacturing business

Starting a concrete block manufacturing business involves several steps, from planning and research to execution and operation. Here's a comprehensive guide to help you get started:

1. Market Research and Business Plan

Market Analysis: Research the demand for concrete blocks in your target area. Identify potential customers such as construction companies, contractors, and individual homeowners.

Competition: Analyze your competitors, their pricing, quality, and market share.

Business Plan: Develop a detailed business plan outlining your business goals, target market, pricing strategy, marketing plan, and financial projections.

2. Legal and Regulatory Requirements

Business Registration: Register your business with the appropriate government authorities. Choose a business structure (sole proprietorship, partnership, LLC, etc.).

Permits and Licenses: Obtain necessary permits and licenses for manufacturing and operating a business in your area.

Zoning Laws: Ensure your manufacturing site complies with local zoning laws and regulations.

3. Location and Infrastructure

Site Selection: Choose a location that is accessible for transportation of raw materials and finished products. Ensure the site has adequate space for manufacturing, storage, and office facilities.

Utilities: Ensure the site has access to necessary utilities like electricity, water, and sewage.

4. Equipment and Machinery

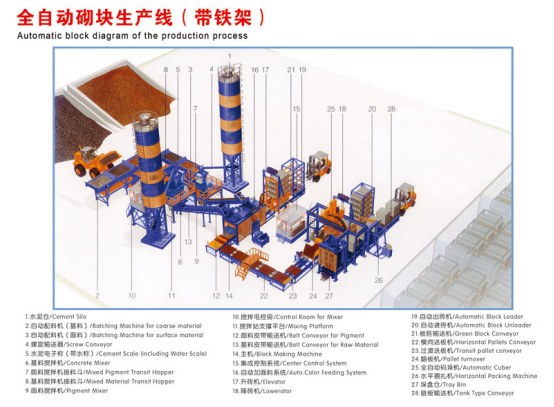

Concrete Block Machine: Invest in a good quality concrete block making machine. There are various types available, including manual, semi-automatic, and fully automatic machines.

Molds: Purchase molds for different types of concrete blocks (e.g., solid, hollow, interlocking).

Mixers and Compactors: Acquire concrete mixers and compactors for preparing the concrete mixture.

Curing Racks: Set up curing racks or areas for the blocks to dry and harden properly.

5. Raw Materials

Cement: Source high-quality cement from reliable suppliers.

Aggregates: Obtain sand, gravel, and other aggregates needed for the concrete mixture.

Water: Ensure a consistent supply of clean water.

Additives: Consider using additives to improve the quality and durability of the blocks.

6. Production Process

Mixing: Mix cement, aggregates, water, and any additives in the correct proportions.

Molding: Pour the mixture into molds using the block-making machine.

Curing: Allow the blocks to cure properly to achieve the desired strength and durability.

Quality Control: Implement quality control measures to ensure the blocks meet industry standards.

7. Staffing

Skilled Labor: Hire skilled workers for operating machinery, mixing, molding, and curing processes.

Management: Employ or appoint managers to oversee operations, quality control, and logistics.

Training: Provide training to your staff on safety protocols and efficient production techniques.

8. Marketing and Sales

Branding: Develop a strong brand identity, including a business name, logo, and marketing materials.

Networking: Build relationships with construction companies, contractors, and suppliers.

Advertising: Use online and offline advertising methods to promote your business. Consider creating a website and using social media platforms.

Distribution: Set up a distribution network to deliver your products to customers efficiently.

9. Financial Management

Budgeting: Create a budget for initial setup costs, operational expenses, and marketing.

Funding: Secure funding through personal savings, loans, or investors.

Pricing: Set competitive pricing for your products while ensuring profitability.

Accounting: Implement an accounting system to track income, expenses, and profits.

10. Scaling and Expansion

Feedback: Collect feedback from customers to improve your products and services.

Diversification: Consider diversifying your product line to include different types of concrete blocks or related products.

Expansion: As your business grows, explore opportunities for expanding your production capacity or entering new markets.